cleanroom compatible deviceadvanced one pass printing system for signage commercial

Digital print arena is undergoing a transformative shift with the advent of innovative one-pass UV technology. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. One-pass UV’s high-res capability produces sharp, complex imagery and text, fitting for packaging, display, and promotional materials. Moreover, its eco-friendly profile reduces power consumption relative to legacy printing techniques, aiding sustainability efforts.

Digital print arena is undergoing a transformative shift with the advent of innovative one-pass UV technology. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A standout benefit is its capability to output lively, enduring prints across multiple substrate types, e.g., plastics, metals, fabrics. One-pass UV’s high-res capability produces sharp, complex imagery and text, fitting for packaging, display, and promotional materials. Moreover, its eco-friendly profile reduces power consumption relative to legacy printing techniques, aiding sustainability efforts. Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes.

Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes. Single-Pass UV Advancements

Digital high-speed printing historically pursues efficiency. Traditionally jobs used several passes, boosting production time and misalignment possibilities. Yet the arrival of Single-Pass UV is changing that landscape. By curing inks with ultraviolet light on a single pass, it achieves substantial speed and precision enhancements.Single-run UV attains vibrant tones and precise clarity, offering superior detail and color depth. This suits demanding uses like large-scale packaging, billboards, and promotional work where rapidity and impact matter. With ongoing development, single-pass UV will likely bring additional innovations toward faster, flexible, and affordable production.

Single-Pass UV Printers: Precision at Pace

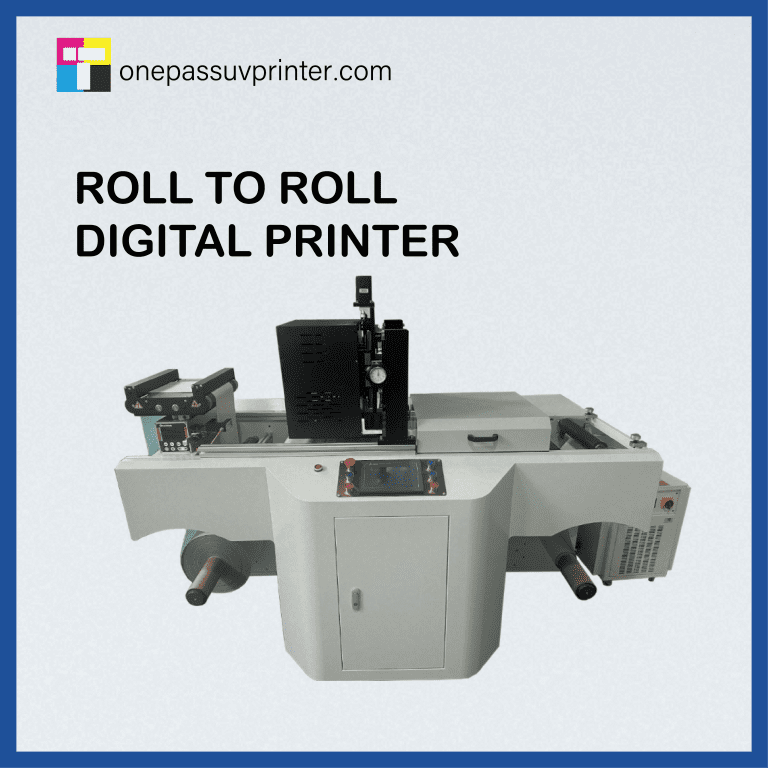

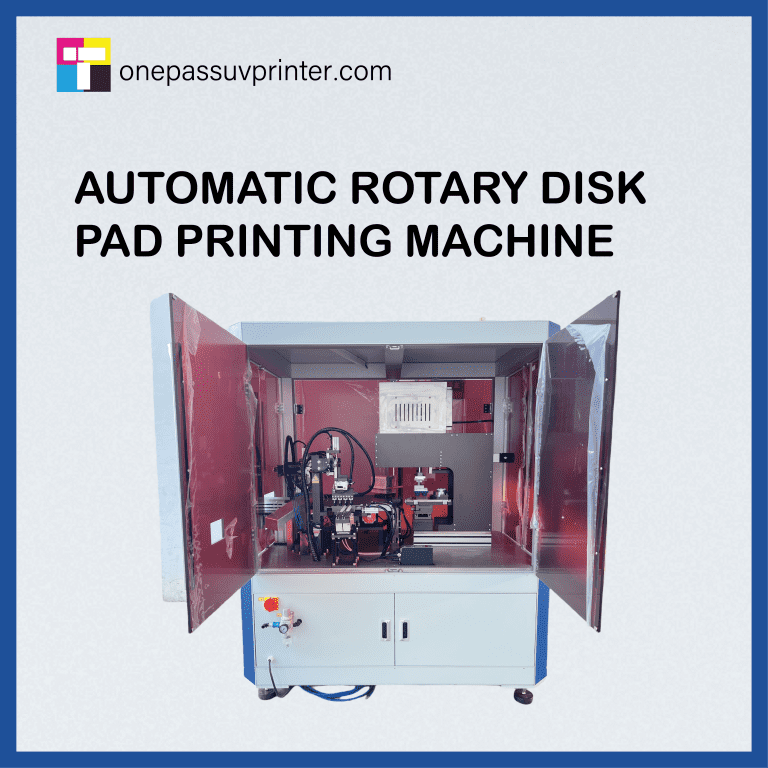

Across the printing sector, single-pass UV printers now stand out as transformative tools improving speed, precision, and operational efficiency. These units use UV light to cure inks instantly, supporting unmatched production velocity. Their single-run multi-color process affords outstanding resolution and strong, accurate color reproduction. From custom short runs to mass commercial production, they support diverse applications, helping companies meet growing market needs.Elevate Your Printing Process

Prepare to be blown away by the single-pass UV printer - a powerful printing solution that redefines industry standards. This inventive machine relies on UV light to cure inks instantly in one pass, achieving superior image quality and resolution.- Enjoy striking color fidelity with fine detail

- Increase production velocity with rapid print tech

- Open new design avenues with an extensive substrate range

High-Throughput UV Printing: Delivering Unmatched Efficiency

UV printing has modernized graphics production with faster cycles, accurate results, and vivid color. Still, high-velocity UV printing amplifies those positives, driving extraordinary production efficiency. This technology utilizes specialized printers capable of outputting high-resolution images at incredible speeds. Because of instant curing and negligible drying, high-speed UV refines workflows to help companies satisfy even tight, heavy orders. High-speed UV’s benefits also encompass quality enhancements in addition to efficiency. It ensures premium print quality, dependable durability, and extensive application options. From packaging and signage to labels and promotional pieces, high-speed UV printing revolutionizes workflows enabling firms to innovate and excel.

One-Pass Production: The Ultimate Solution for Fast Turnaround Times

In the modern quick-turn economy, speed rules. For print production, fast and efficient systems are essential. One-Pass Print fills that gap. It facilitates printing in a single pass, removing multiple cycles and trimming processing duration. One-Pass Print enables greatly faster turnarounds, freeing staff and resources. Hence, businesses of varied sizes can capitalize on One-Pass Print advantages. From promotional pieces to critical documents, the tech enables timely printing without sacrificing quality.Single Pass UV: Speed and Quality United

In present manufacturing systems, efficiency is critical. Producers demand methods that deliver exceptional quality without sacrificing production speed. Single-pass UV comes forward as an innovative approach combining high-res inspection and instant cure. The technique applies ultraviolet curing to inks and coatings to deliver long-lasting vibrant finishes with less production time. Single-pass UV’s accuracy results in flawless goods meeting demanding quality norms. The perks stretch beyond improved speed and print quality. Single Pass UV reduces waste by eliminating the need for lengthy drying times, contributing to a more sustainable production process.- Moreover, the adaptable nature of single-pass UV suits fields from packaging and printing to electronic manufacture.

Innovating Digital Printing with High-Speed UV

Printing continues to change under constant pressure for faster performance, finer precision, and novel technology. Fast UV technology has arisen as a key disruptor, marrying speed with precision and flexibility. UV printing applies UV light to cure inks at once, eliminating drawn-out drying and unlocking new use cases. This fast curing mechanism supports superior print speeds, markedly reducing production time and enhancing efficiency. Moreover, UV inks deliver strong longevity and resistance to fading, scratches, and moisture, ideal for many uses. From colorful signage to durable product packaging, fast UV printing is redefining printing standards.- Gains

The Age of Immediate Photos: UV Printing in Action

In speedy graphics and single pass uv printer imaging sectors, time is a critical asset. Customers require fast delivery times while businesses must supply top-quality prints on demand. Enter one-pass UV printers, supplying disruptive solutions for today’s printing challenges. These sophisticated printers deploy UV inks that set instantly with light exposure, avoiding lengthy drying phases. Resulting in instant prints with vivid colors and durable results. Consequently, one-pass UV printers are finding applications in a wide range of industries. From retail and e-commerce marketing to photography, fine art, and manufacturing, organizations use instant printing. Applications include creating custom items, producing tailored signage, and making eye-catching marketing collateral. The perks stretch beyond speed and workflow improvements. One-pass UV systems supply precise color reproduction, high-resolution output, and versatile substrate handling for complex projects.- Furthermore, one-pass UV printing is an environmentally friendly option as it requires no harsh solvents or volatile organic compounds (VOCs).

- To summarize, instant-print technology is established: with speed and versatility, one-pass UV is altering printing toward greater efficiency.

Modernize Your Workflow with Single-Pass UV

Optimize production processes and reach improved efficiency with a single-pass UV system. This advanced method enables bright, high-res printing directly on many substrates in a single pass, removing multi-step layering.- Achieve remarkable speed and lower production timelines.

- Maximize your output with a faster turnaround time for orders.

- Employ UV ink’s lasting precision to achieve durable vibrant prints.

The Benefits of Single-Pass UV in High-Impact Printing

Single-pass UV printing is now recognized as a breakthrough for high-impact applications. Using UV to cure ink instantly, this method brings significant advantages beyond traditional processes. Firstly, single-pass UV printing provides unparalleled image quality due to its ability to produce highly vibrant colors and crisp details. Eliminating drying time through UV curing raises productivity and shortens turnaround.- Moreover, the method creates hard-wearing prints that resist fading, scratching, and abrasion.

- Overall, the combination of high image quality, increased throughput, and durable output makes single-pass UV attractive for high-impact printing.